ENGINEERING

Engineering being our core, any project undertaken, may it be a simple component or a complex assembly, flows through our following engineering proficiencies to achieve techno-commercial finesse in the array of Metal Forgings

Our comprehensive and practical knowledge of various Forging Standards and processes such as... Closed Die, Open Die, Cold Forge, Upset Forge enables us to select the most suitable combination of Forging processes and machines that in turn achieves the most desirable Cost / Precision / Volume / Time efficiency matrix.

Having penetrative abilities to understand clients' product key attributes, its functional requirements & desir...ed specifications, we contemplate on vital process parameters such as Physical, Micro Structural Properties, Plasticity, Friction, Strain Hardening, Forging Rate, Billet Temperature and Die Geometry etc. and appropriately design customized development and manufacturing plans to achieve an optimized techno-commercial product.

Our core competencies are in handling Forging & Stamping having intricate Shapes & Complex Profiles includ...ing non-symmetrical and thin sections, odd sizes etc. with Close Tolerances and Geometric Accuracy of various types of Ferrous, Non Ferrous & other non-metallic raw materials.

We are apt to envisage & encounter process defects and limitations such as Folds, Under filling, Oversize, Quen...ch Cracks, poor Grain structure, Mismatch, Scale Pitting & Segregation and in corporate predefined remedies while designing the manufacturing plans.

We stand ready with our backward integration expertise and value engineering initiatives to revisit design paramete...rs and render optimum manufacturability solutions such as suggesting alternate alloys to maximize forging output, CAD / CAM support for dimensional accuracy, Flow & Thermal Simulation to reduce development time thereby designing the Ideal tooling and process with minimal flash and material wastage etc.

We provide comprehensive support in product design & development using advanced tools such as 3D Software, Fini...te Element Analysis (FEA) etc. for in-depth understanding of clients specifications & Interfacing in further operations and subsequently assisting our Tool Makers & Forgers to profoundly understand the Job Profile leading to an optimized forging production process thus adding value to clients' end product quality.

Our engineers have meticulous knowledge of manufacturing engineering, Tool design-development and preventi...ve maintenance systems supported by tool room for Forgings Dies, Tools, Jigs, Fixtures, Gauges and Special inspection devices to achieve mass production with consistent quality at minimal inspection.

Our strategic tie-ups with strong networks of consulting Technical Experts, R&D Institutes and laboratories ded...icated to Forging / Stamping / Metal Gathering processes assist us in enhancing our competencies.

Our post-manufacturing and supportive activities like Surface Treatment, Heat Treatment, Final Machining, other al...lied processes and assembling, added with customized packaging makes us a Total Solution Provider to our Clients.

MANUFACTURING

Manufacturing setup with our associated production units, vendors & subcontractors comprises of…

FORGING SHOPs (equipped with):

|

HEAT TREATMENT SHOPS : To cater Large Jobs for:

|

TOOL ROOM with SIMULATION SOFTWARE To produce tooling such as:-

|

INSPECTION FACILITIES Equipment & measuring instruments for precision in manufacturing, such as…

|

CONSULTING R&D INSTITUTES & TESTING LABS DEDICATED TO FORGINGS

|

We process raw materials of various International Standards like DIN, BS, ASTM, EN, JIS, ISI etc.

Non-Ferrous Metals

|

Ferrous Metals

|

Specialty Materials

|

Sheet Metal Forms Utilized : Blocks, Thick Sections, Bar Stocks, Coils & Wires

As a part of our total solutions approach, we also undertake auxiliary and allied processes encompassing…

- Surface Strengthening and Finish: Shot Blasting, Shot Peening, Sand Blasting, Polishing, Buffing etc

- Heat Treatments: Solution Annealing, Nitrogen Annealing, Spherodising etc

- Machining Operations as per the design specifications

- Surface Platings / Coatings: Zinc Passivation, Nickel Plating etc

- Specialty Surface Plating / Coatings: Silver, Tin, Electroless Nickel, Hard Chrome Plating etc

All our Products are manufactured in adherence to our Quality Policy & Work System manuals. Please visit our Quality page & Work manuals for an in depth understanding of our Procedures & Systems. Additionally, Quality procedures specific to Our Forged components manufacturing are…

- Typical Testing & Inspection inclusive of Raw Material & Forgings for Chemical Composition and Physical Properties, Microstructure, Tensile Test, Radiography, Hardness Test, Liquid Penetrant Testing, Ultrasonic Testing, Magnetic Particle Inspection, etc are performed as per the desired specifications

- Specialized Mechanical Testing such as Shock Resistance Test, Creep Strength Test, Surface Roughness Tests and Salt Spray Testing are performed as per the desired specifications

- Additional customized & comprehensive quality tests as per client drawings / specifications, inclusive of Accurately Designed Inspection Gauges and Devices

PRODUCTS & IT'S APPLICATIONS

Our value engineered & manufactured rubber & polymer components & assemblies with focus on our client’s intent, find their infinite customized applications across all engineering industries.

- Automotive, Trailers & Off Road Vehicles

- Electrical & Energy

- Marine Electricals

- Motion Conveyance & Material Handling

- Hydraulics Pumps Motors & Valves

- Compressors Pneumatic Tools

- Climate Control & Refrigeration

- Architecture & Glass Hardware

- Irrigation & Agricultural Machinery

- General Industrial Equipment Hardware & Fasteners

ACHIEVEMENTS

From simple upsetting / forming to precision closed die forgings, COREiNSPIRE has achieved its ingenuity to cutting edge products applied across various electrical, mechanical & automotive industries that highlight its core competencies.

Here are a few products of ferrous & non-ferrous metals, developed & manufactured by a variety of forging processes that underpin our achievements:

FORGED SWITCH TERMINALS

GEAR BOX SYNCHRONIZER RING

SINGLE CYLINDER CAMSHAFT

U.J. CROSS HOLDER

AUTOMOTIVE DRIVE LINE FLANGE

PRECISION MACHINED COMPONENTS

PRECISION MACHINED COMPONENTS SHEET METAL PRESSED & FORMED COMPONENTS

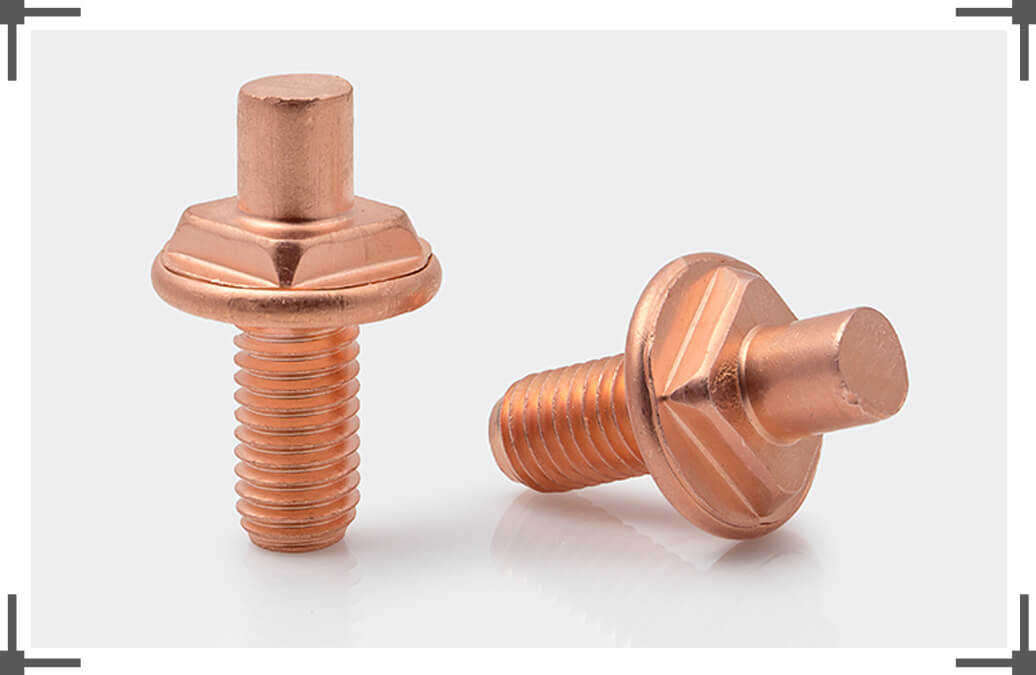

SHEET METAL PRESSED & FORMED COMPONENTS COPPER, BRASS & NON FERROUS COMPONENTS

COPPER, BRASS & NON FERROUS COMPONENTS FABRICATED COMPONENTS & ASSEMBLIES

FABRICATED COMPONENTS & ASSEMBLIES FORGINGS

FORGINGS CASTINGS

CASTINGS RUBBER & POLYMER COMPONENTS

RUBBER & POLYMER COMPONENTS ASSEMBLY ENGINEERING

ASSEMBLY ENGINEERING PLASTIC COMPONENTS & ASSEMBLIES

PLASTIC COMPONENTS & ASSEMBLIES SPRINGS & WIRE FORMS

SPRINGS & WIRE FORMS